There are major differences between how Cura handles print profiles and how SupersSlicer handles print profiles. In my opinion, SuperSlicer separates the functionality a lot better than Cura. Profiles settings are separated into 3 areas, each having a single responsibility. Getting your head around how custom slicer profiles work is daunting. I found that a solid naming structure for your custom profiles is key to understanding how they work, and for successfully using PrusaSlicer as well as SuperSlicer. This article is written using SuperSlicer as the example, but the profile naming schema applies to PrusaSlicer as well.

Before I get to the custom 3d printer profile naming structure. Lets talk about the 3 tabs in the slicer:

- Printer Settings

- Filament Settings

- Print Settings

You may have noticed this is reverse order compared to the SuperSlicer interface. I am explaining them in this order because it relates to how I manage my slicer profiles, and how the system in general works.

Sanity Sake: Print and Printer are just too similar, so I refer to Printer settings as Machine Settings and abbreviate it as such in the schema.

With the advent of advanced printing methods like pressure advance, perfecting your prints becomes more of a per filament setting. As far as per filament goes, I am referring to a specific setup/tune for a certain brand and type of filament. Lets say 3D Fuel PLA Pro. This PLA Pro filament prints differently than the PLA of the same brand, hence it needs specific settings. SuperSlicer plus my naming scheme, you will be good to go.

Without getting too deep in to the dependencies as you transit from the machine settings to print settings, just know that you will not be able to use the same print profile for different nozzle sizes.

Setting Abbreviation | Nozzle Size | Filament Abbreviation

MS | 4N | PLA

Machine Settings | .4 Nozzle | PLA Filament

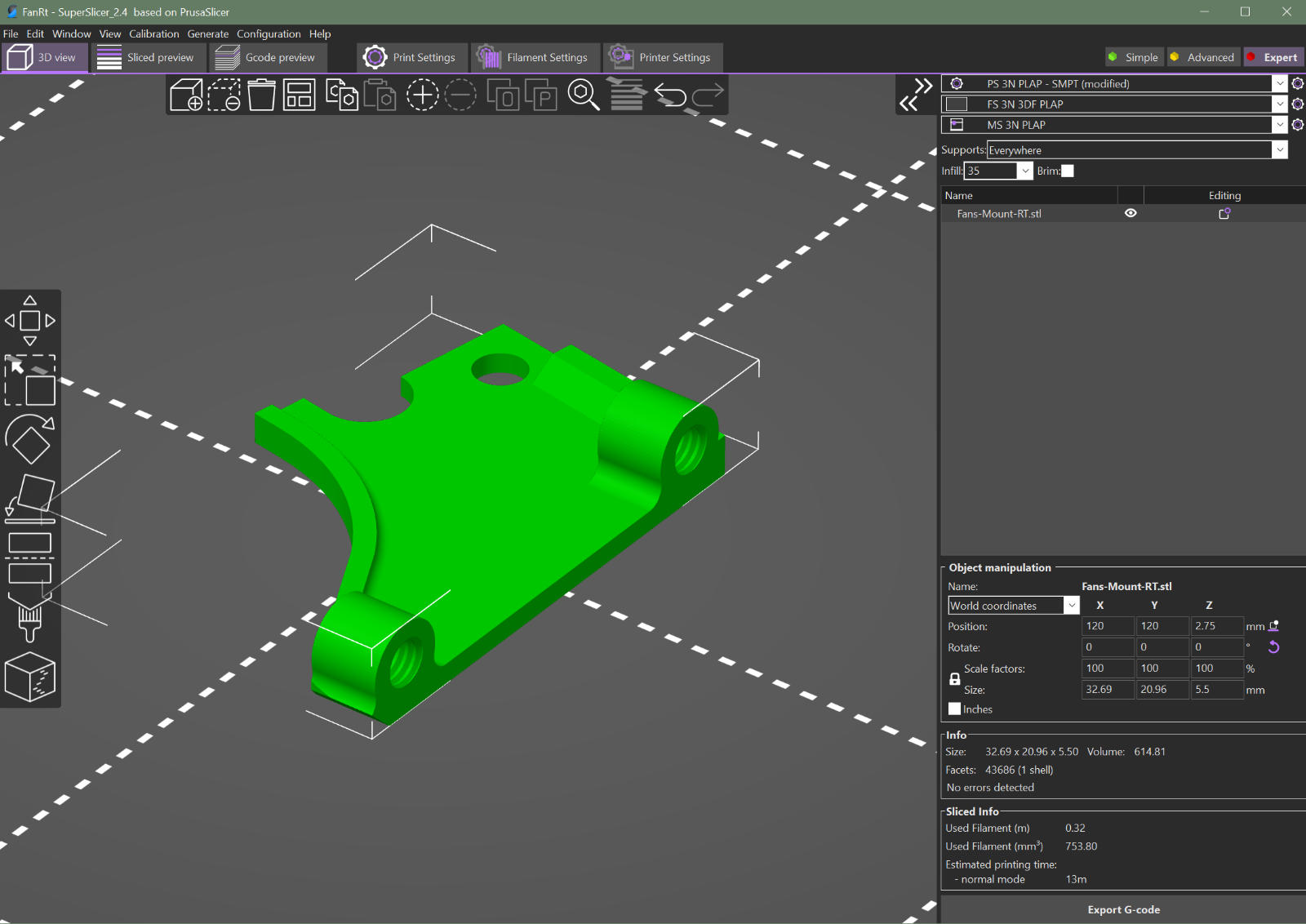

Follow along in the image above to see all three types of profiles side by side.

Machine Settings (Printer Settings)

MS 3N PLAP

This is the machine settings for a .3mm nozzle using PLA Pro filament. At this level I don't think it is necessarily advantageous to set this per brand. But you will need a different profile for each nozzle size with a companion filament type. You can certainly do one profile for multiple filament types, lets say you have a PLA and a PLA+ that don't need a different retraction distance. You can group these.

Machine settings can have different minimum and maximum layer heights as well as change retraction on a per filament basis. I find that PLA Pro needs a little more retraction than standard PLA.

Filament Settings

FS 3N 3DF PLAP

This is the filament settings for a .3 nozzle using 3D Fuel PLA Pro filament.

Filaments settings can have different filament diameter and extrusion multipliers. I find that the extrusion multiplier changes on a per nozzle and per filament type basis.

Print Settings

PS 3N PLAP

This is the printer settings for a .3 nozzle using PLA Pro filament.

These are the main settings for your slice/print.